doi: 10.62486/latia2024103

ORIGINAL

Color in images: a machine vision

approach to the measurement of CIEL*a*b* coordinates in bovine loins

El color en imágenes: un enfoque de

visión artificial para la medición de coordenadas CIEL*a*b* en lomos de bovino

Olga Lucía Torres Vargas1 *, Mateo Valencia Buitrago1 *

1Universidad del

Quindío. Colombia.

Cite as: Torres Vargas

OL, Valencia Buitrago M. Color in images: a machine vision approach to the

measurement of CIEL*a*b* coordinates in bovine loins. LatIA. 2024; 2:103. https://doi.org/10.62486/latia2024103

Submitted:

03-02-2024 Revised: 09-05-2024

Accepted: 15-08-2024 Published: 16-08-2024

Editor: Prof.

Dr. Javier González Argote

ABSTRACT

Electronic machine vision systems bring together a

set of technologies and techniques used to capture, process and analyze images

to perform a specific task, such as object or measurement pattern recognition.

These systems rely on image processing and machine learning algorithms to

interpret visual information. Therefore, the objective of this research was the

construction of an electronic machine vision system (SVA) for color analysis in

bovine (longisimus dorsi) loins based on the CIEL*a*b* color space. The VAS

implementation was carried out using the programming language Python 3.9

programming language and the color parameters obtained were compared with those

obtained on a Minolta CR-400 colorimeter (CM). Both systems were synchronized

to provide the user with information about the color coordinates in the samples

of loins stored for 6 days at 4°C. The results obtained showed no significant

differences. The results obtained showed no significant differences in the

values of the L* parameter, while b* and a* showed significant differences

during the storage time of the loins. These results are attributed to the

oxidation process of the myoglobin and to factors such as breed, feeding and

slaughtering process of the cattle, which affect the color of the samples. The

results obtained indicate that VAS could be used for the determination of color

during the storage of beef loins in real time, offering a non-invasive and

low-cost solution to the actors in the meat chain.

Keywords:

Image Analysis; Beef; Colorimeter; Artificial Vision System.

RESUMEN

Los

sistemas electrónicos de visión artificial reúnen un conjunto de tecnologías y

técnicas utilizadas para capturar, procesar y analizar imágenes que realizaran

una tarea específica, como el reconocimiento de objetos o patrones de medida.

Estos sistemas se basan en algoritmos de procesamiento de imágenes y aprendizaje

automático para interpretar la información visual. Por lo tanto, el objetivo de

esta investigación fue la construcción de un sistema electrónico de visión

artificial (SVA) para el análisis de color, en lomos de bovino (longisimus

dorsi) fundamentado en el espacio de color CIEL*a*b*. La implementación del

SVA se llevó a cabo utilizando el lenguaje de programación Python 3.9 y los

parámetros de color obtenidos fueron comparados con los obtenidos en un

colorímetro Minolta CR-400 (CM). Ambos sistemas fueron sincronizados para

proporcionar al usuario información acerca de las coordenadas de color en las

muestras de los lomos almacenados durante 6 días a 4°C. Los resultados

obtenidos, no presentaron diferencias significativas en los valores del parámetro

L*, mientras que b* y a* presentaron diferencias significativas durante el

tiempo de almacenamiento de los lomos, estos resultados son atribuidos al

proceso de oxidación de la mioglobina y a factores como la raza, la

alimentación y el proceso de sacrificio de los bovinos, que afectan, el color

de las muestras. Los resultados obtenidos indican que el SVA podría ser

utilizado para la determinación del color durante el almacenamiento de lomos de

bovino en tiempo real, ofreciendo una solución no invasiva y de bajo costo a

los actores de la cadena cárnica.

Palabras

clave: Análisis de Imagen; Carne de Bovino;

Colorímetro; Sistema de Visión Artificial.

INTRODUCTION

Color

is one of the organoleptic characteristics that most influences the

acceptability of meat and plays an important role in the consumer's purchasing

decision (Parra et al., 2021). One of the problems presented by the evaluation

of color is the methodology used to obtain significant information, which makes

it possible to compare and improve meat products in a versatile, rapid, and

on-site manner. Color measurements in foods are usually carried out with

digital colorimeters, which, although easy to use and calibrate, have

limitations such as cost, specialized maintenance, the size of the measurement

area, and the need for contact with the surface to be measured (Sanmartín et

al., 2021). Therefore, it is important that color assessment is performed consistently

and objectively to obtain reliable and reproducible results that reflect human

perception and can be performed in a non-invasive manner (Wu & Sun, 2013).

The

CIEL*a*b* color space has proven to be one of the most suitable for color

assessment in the food area; it correlates numerical color values consistently

with human visual perception (Anilkumar et al., 2021). This Cartesian system

consists of three axes: L* vertical, informs us of the degree of lightness or

brightness of a color (Wyszecki & Stiles, 2000) and can take values between

0 (black) to 100 (white); a* horizontal, indicates the content of red (+a*) or

green (-a*); and b* horizontal and perpendicular to a*, which represents the

content of yellow (+b*) or blue (-b*).

Studies

using VAS for color assessment have focused on converting images obtained using

the RGB color measurement system to the CIEL*a*b* system (Larraín et al.,

2008). Analysis of pork loin quality using an online VAS and an artificial

intelligence model indicated that VAS could provide an effective tool for

predicting color and marbling in pork on processing lines in real time (Sun et

al.,2018). SVA and embedded systems were used as alternatives to evaluate the

freshness of beef, using principal component analysis (PCA) and support vector

machines (SVM); the results show that the proposed system can successfully

predict freshness, suggesting its feasibility for on-site and real-time use

(Arsalane et al., 2020). VAS can accurately determine the color of meat

products in CIEL*a*b* space, ensuring the quality of their products through

fast and accurate assessment, characteristics that, in turn, can influence

consumer perception and business profitability (Nasiri & Mohi, 2021).

Altmann et al. (2022) analyzed the methodology of human perception of color

differences in raw pork using a computer vision system. Modzelewska-Kapituła

& Jun (2022) performed VAS applications in volume and surface area

measurement, quality assessment, meat chemical composition determination, and

sensory quality prediction. Developing a VAS that can accurately determine

color in the CIEL*a*b* space of images in bovine loins is an invaluable tool

for the meat industry (Nasiri & Mohi, 2021). Therefore, the development of

VAS for color analysis in meat products has become relevant due to its

importance as an indicator of meat quality (Nasiri & Mohi, 2021).

METHOD

The

project presented below was carried out in two stages. The first stage involved

the construction of an artificial vision electronic system (SVA) for the color

analysis of Longissimus dorsi bovine loins and their physical components. The

loins were acquired from a supermarket in Armenia, Quindío, with Invima

certification for their commercialization. The hardware measurement system was

programmed in the Python 3.9 system in the second stage. Both systems, duly

synchronized, present the CIEL*a*b* coordinates to the user in fresh beef

samples (slaughtered on day zero) and stored for six days at four °C, as

explained below.

Configuration

of the Raspberry Pi 4 for image capture and processing in CIEL*a*b* color space

To

ensure efficient capture and processing of high-quality images and the speed

needed for the application, the selection of the VAS hardware is crucial. It

depends on the level of accuracy and the environment of use. Essential

components include high-resolution cameras, image processors, graphics

processing units (GPUs), and data storage devices, which must be carefully

chosen to ensure the system meets the required functions. The components

presented in table 1 were used to construct the obtained VAS.

|

Table 1. Hardware components used in the construction of the machine

vision system (SVA)

|

|

|

Description

|

Characteristics

|

|

Raspberry pi 4

|

The Raspberry Pi 4 is

a single board computer (SBC) developed by the Raspberry Pi Foundation. It is

a newer, more powerful version of the Raspberry Pi series of computers, known

for its compact size, low cost, and

versatility.

|

·

Processor: Broadcom

BCM2711 quad-core processor

·

RAM memory: 4 GB

·

GPIO: Retains the GPIO

(General Purpose Input/Output) interface that allows connection of external

electronic components and peripherals.

·

Connectivity: Offers a

variety of connectivity options, including USB 3.0 and 2.0 ports, Gigabit

Ethernet connection, dual-band 802.11ac Wi-Fi and Bluetooth 5.0

|

|

Camera

|

The Logitech PRO C920

is a high-quality webcam that offers an excellent combination of video

resolution, image quality, clear audio and ease of use.

|

·

Video resolution: The C920

captures Full HD 1080p video at 30 frames per second.

·

Automatic lighting

correction: Incorporates automatic lighting correction technology that

automatically adjusts exposure and white balance.

|

|

Lighting

|

White LED strip,

lighting device consisting of a series of white LEDs arranged in an elongated

and thin structure.

|

·

The power consumed by the

entire strip is 14.9W, which generates a luminous efficacy of 148l m/W.

|

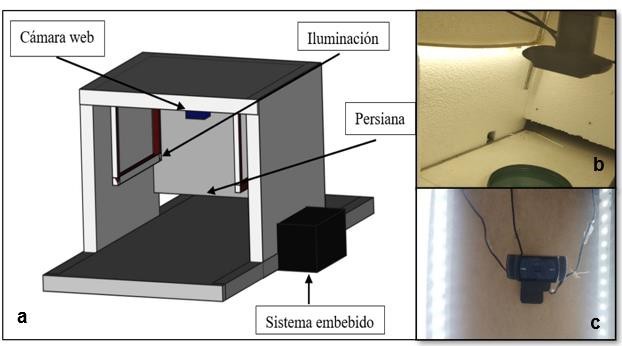

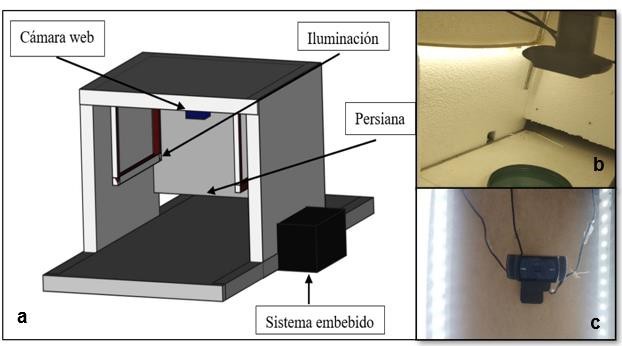

To ensure the proper functioning of the VAS, a black

film was placed on the outer surface of the equipment, which prevents the

passage of light into the measuring compartment of the sample image (figure 1),

which is covered by a white film on the inside. Both films eliminate the

interference of external light and stabilize the reflection of the light inside

the measuring compartment.

Figure

1. a) Machine Vision System (SVA) for color

measurement and analysis of bovine loin samples, b) Internal compartment of the

SVA, c) Positioning of the camera and the illumination system

Image

acquisition process in the Machine Vision System (SVA)

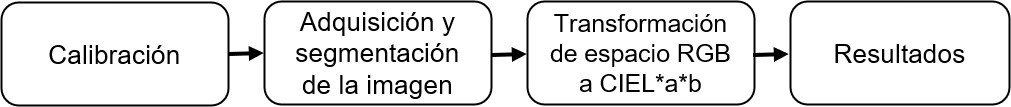

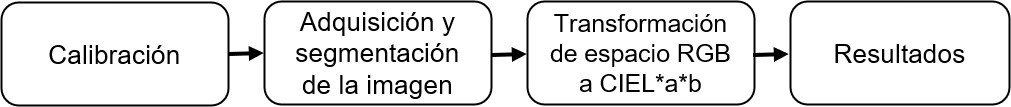

For the implementation of a VAS according to the

requirements proposed and taking into account the characteristics of the

hardware acquired, we proposed the design of software that allows the

calibration of the camera and the detection of the color of the bovine loins,

following the stages proposed in the block diagram shown in figure 2. An

embedded system conforms to the central axis of this stage; such a system was

implemented in a Raspberry Pi 4, running the Raspberry Pi OS, which is in

charge of capturing the image, segmenting it, resizing it, storing it, and

delivering a response in terms of the CIEL*a*b* system to the user.

Figure

2. Stages established in the design and

construction of the software for the Machine Vision System (SVA)

Once the synchronization of the equipment was

completed, the calibration stage was performed. The focal length and optical

center obtained in the camera calibration matrix are presented in table 2.

These values were used in the calibration function to obtain a better image

resolution at the moment of capturing the focal length (fx, fy), optical

centers (cx, cy), and the comparison of the image obtained in the uncalibrated

camera, as shown in figure 3.

|

Table 2. Logitech

PRO C920 camera intrinsic parameter values

|

|

Parameters

|

Value

|

|

fx

|

956.602

|

|

fy

|

103.179

|

|

cx

|

291.159

|

|

cy

|

73.680

|

A Logitech PRO C920 camera was used to determine the

color, which offers advantages such as capturing a large amount of spatial

information, the ability to measure surfaces of various sizes, availability of

a wide range of models at more affordable prices and does not require direct

contact with the surface to be measured. However, using theoretical models, the

information obtained in color space Red, Green, and Blue (RGB) must be

transformed to CIEL*a*b* color space (Castellanos et al., 2022). The parameters

and equations used at this stage are presented in table 3.

|

Table 3. Characterization of color in bovine loins: equations and

specialized equipment

|

|

Parameters

|

Equations

|

Color measurement equipment

|

|

Brightness: L*

|

L*

= 116 (𝑌1/3/𝑌𝑛)− 16 Ec. (1)

|

|

|

Coordinate

|

a* = 500 [(𝑋1/3/ 𝑋𝑛) − (𝑌1/3/𝑌𝑛)] 𝐸𝑐. (2)

|

|

coordinate: a*

|

|

|

b* = 200

[(𝑌1/3/Yn)− (𝑍 1/3Zn] 𝐸𝑐. (3)

|

Colorimeter

CR-400

|

|

Coordinate

|

(Konica Minolta Sensing Americas. ,2023)

|

|

coordinate: b*

|

|

In order to establish a comparison parameter, color

measurements were made in the VAS and the Konica Minolta CR-400 colorimeter (table

3), taking the color coordinates L*, a*, and b* in five points of each sample

of fresh beef loins and stored for six days, the reported values were

calculated as the average of these measurements. The determination and

expression of color were carried out based on the CIEL*a*b* coordinates (table

3) and reflectance values (CIE, 1976), obtaining the coordinates: Luminosity

(L*), red-green (a*), yellow-blue (b*), directly from the equipment.

RESULTS AND DISCUSSION

The results obtained during the realization of the

project are presented below; once the construction of the electronic system and

the programming of the VAS hardware measurement system in its structural form

were completed, a compartment was built for the acquisition of the images,

which functions as the main structure of the equipment it supports the sample

of bovine loins to be analyzed and the other components, as shown in figure 1.

Image

capture and extraction of CIEL*a*b* coordinates in the VAS

The image capture process performed by the VAS is

fundamental for the acquisition of visual data that will be used in the

analysis of the color of the spines and subsequent analysis. Figure 3 shows the

different stages performed in SVA during image capture, calibration, and

segmentation. Initially, the environment and the sample of bovine loins were

prepared, ensuring optimal illumination and alignment conditions that allowed

an accurate capture of the image (figure 3a). The focal length and optical

center obtained in the camera calibration matrix are presented in table 2.

These values are used in the calibration function to obtain a better image

resolution at the time of capture and compare with the image obtained in the

uncalibrated camera.

The image was captured using the Logitech PRO C920

camera, and an analysis process was performed to reduce noise and improve its

quality. Contrast and color correction adjustments were also made to optimize

its usefulness in subsequent analyses (figure 3b). Once the previous process

was finished, image segmentation was performed to identify the region of

interest (ROI) within the complete image of the bovine loin obtained (figure

3c). This segmentation involved using advanced image processing techniques, such

as thresholding and feature detection, to distinguish the ROI from the

background and other irrelevant elements. The identified region of interest

becomes the main focus of further analysis and applications, allowing feature

detection, pattern recognition, and decision-making based on accurate and

relevant visual information.

|

|

|

|

|

a)

Uncalibrated image

|

b) Calibrated image

|

c) Segmented image

|

Figure

3. Image

of bovine loin a) before and b) after the calibration process, and c) segmented

image

Once

the previous steps were completed, the measurement was performed, and the

values of the parameters L*, a*, and b* were extracted from the image obtained

from the bovine loin. The image acquired by Python 3.9 software was converted

from RGB space to CIEL*a* b* space, using equations (1), (2), and (3) presented

in table 3. The system calculates the mean of the Luminance (L*), red-green

(a*), and yellow-blue (b*) coordinates. Finally, the user will be able to

visualize in the interface the two components facing the original image of

bovine loins during the days (0-6) of storage at four °C, as presented in table

4.

Comparison

between the color measurements obtained in the Machine Vision System (SVA) and

the Minolta CR-400 Colorimeter (CM)

The

color coordinates L*, a*, and b*, obtained in the VAS, were compared with those

obtained in the CM and presented in table 4. In order to obtain the color

values in the CM, it was necessary to take measurements in several sections of

the sample and obtain average values because the analysis area of the

colorimeter is approximately 8 mm in diameter and was not able to cover the

total area of the meat samples, connective tissue and intramuscular fat that

could influence the colorimetric characteristics of the lean part of these

(Girolami et al., 2013).

|

Table 4. CIEL* a* b* coordinates in beef loin samples during storage

time at four °C, acquired in the Machine Vision System (SVA) and the Minolta

CR-400 Colorimeter (CM)

|

|

Sample

|

Storage

time

|

CIEL

coordinate values *a* b*

|

|

SVA

|

CM

|

|

|

|

L*: 59.61186178

|

L*: 60.48523865

|

|

Día 0

|

a*: 5.3776992

|

a*: 5.96368978

|

|

|

b*: -8.3727804

|

b*: -9.44569322

|

|

|

|

L*: 58.27551214

|

L*: 58.26325783

|

|

Día 1

|

a*: 5. 64158818

|

a*: 5.

89857451

|

|

|

b*: -9.77889147

|

b*: -10.80364578

|

|

|

|

L*: 50.12012421

|

L*: 49.85823695

|

|

Día 2

|

a*: 2.64234985

|

a*: 2.59834857

|

|

|

b*: -4.39190818

|

b*: -5.52364735

|

|

|

|

L*: 51.35447075

|

L*: 50.56891525

|

|

Día 3

|

a*: 2.35686958

|

a*: 2.56457985

|

|

|

b*: -4.21038999

|

b*: -4.32659524

|

|

|

|

L*: 61.63334934

|

L*: 50.85621394

|

|

Día 4

|

a*: 3.06043796

|

a*: 3.84785622

|

|

|

b*: -4.96354232

|

b*: -5.29425367

|

|

|

|

L*: 48.91479247

|

L*: 49.09458236

|

|

Día 5

|

a*: 2.94847217

|

a*: 3.52584793

|

|

|

b*: -4.34895065

|

b*: -3.95864127

|

|

|

|

L*: 48.23733609

|

L*: 48.18945633

|

|

Día 6

|

a*: 1.46530337

|

a*: 1.98647817

|

|

|

b*: -2.86972267

|

b*: -3.99857426

|

Samples:

Bovine loins, Equipment: SVA: machine vision system, CM Minolta colorimeter,

storage time (Dia 0-6), L*, a* and b* color coordinates.

The values obtained in the VAS of beef loin samples

represent the sample as a whole. They can be observed from the equipment

monitor, making it possible to guarantee homogeneous measurements of the lean

parts or those of interest to the researcher. The values obtained for the L*

coordinate showed similar trends in the two measuring devices for the beef

tenderloin samples. This coordinate is related to the total pigment contained

in the meat, making the product darker or more opaque, as can be seen in table 4.

The values of L* decrease with storage time, indicating that L* is useful for

differentiating the color between meat samples during storage time (Xing et

al., 2007).

The a* coordinate is related to myoglobin content,

and the b* coordinate is related to myoglobin states (Perez et al., 1998). The

values obtained for the a* and b* coordinates showed significant differences

between the two measuring devices. They decreased during the first hours of

storage, corresponding to the meat's oxidation stage, causing more pronounced

changes in b*; this behavior can also be attributed to the reflected and

refracted light of the myoglobin and myoglobin layers (Girolami et al., 2013).

Another factor that could influence the values obtained for a and b* is

attributed to the methodology used for image capture in the Minolta Colorimeter

and to factors such as breed, cattle feed, and slaughter process that affect

the oxidation process of myoglobin and, therefore, the color of the meat

samples during storage time.

The processes described above, from constructing the

electronic machine vision system to designing the software for color analysis

in bovine loins, have culminated in significant and promising results. These

results clearly show the feasibility and efficacy of the system developed for

color evaluation in fresh and stored beef samples.

CONCLUSIONS

The color values obtained through the application of

the CIEL*a*b* coordinates and their comparison with the Minolta CR-400

Colorimeter in the samples of fresh beef loins and during the storage time did

not present significant statistical differences about the L* values, the values

obtained for a* and b* presented statistical differences attributed to the

methodology used for the capture of the image in the Minolta Colorimeter and to

factors specific to beef.

The results established that the artificial vision

system can measure fresh beef loins' color during storage time in a simple,

fast, non-invasive, real-time, and low-cost manner.

This technological tool will allow meat producers,

marketers, and processors to take appropriate management measures to obtain

quality products with high consumer acceptance. It also constitutes, at

present, an important open field of research and an excellent opportunity for

electronics and agribusiness, aiming at the generation of science and

technology itself.

BIBLIOGRAPHIC REFERENCES

1. Altmann, B. A.,

Gertheiss, J., Tomasevic, I., Engelkes, C., Glaesener, T., Meyer, J., Schäfer,

A., Wiesen, R., & Mörlein, D. (2022). Human perception of color differences

using computer vision system measurements of raw pork loin. Meat science, 188,

108766. https://doi.org/10.1016/j.meatsci.2022.108766

2. Anilkumar, K. K.,

Manoj, V. J., & Sagi, T. M. (2021). Efficacy of CIEL*a*b* and cmyk color

spaces in leukemia image analysis: a comparison by statistical techniques.

Biomedical Engineering: Applications, Basis and Communications, 33(06),

2150042. http://dx.doi.org/10.4015/S1016237221500423.

3. Arsalane, Assia

& Klilou, Abdessamad & Noureddine, El Barbri & Abdelmoumen,

Tabyaoui. (2020). Artificial vision and embedded systems as alternative tools

for evaluating beef meat freshness. 1-6.

10.1109/ICOA49421.2020.9094503.

4. Castellanos Tolosa, N y

Sánchez Jiménez, M. (2022). Desarrollo de carne de hamburguesa a base de harina

de grillo. Universidad de los Andes. Disponible en: http://hdl.handle.net/1992/55654.

5. Girolami, A., Napolitano, F.,

Faraone, D., & Braghieri, A. (2013). Measurement of meat color using a computer vision system.

Meat science, 93(1), 111–118. https://doi.org/10.1016/j.meatsci.2012.08.010.

6. Larraín, R.,

Schaefer, D., Reed, J. (2008). Use of digital images to estimate CIE color

coordinates of beef. Food Research International, 41(4), 380-385. DOI:

10.1016/j.foodres.2008.01.002.

7.

Modzelewska-Kapituła, M., & Jun, S. (2022). The application of computer

vision systems in meat science and industry–A review. Meat Science, 192,

108904. DOI: 10.1016/j.meatsci.2022.108904.

8. Nasiri, A., &

Mohi, K. (2021). A machine vision-based system for measuring the chromatic

parameters of bell pepper using artificial neural networks.

9. Parra-Bracamonte, G. M., López-Villalobos,

N., Vázquez-Armijo, J. F., Magaña-Monforte,

10. J. G., Martínez-González, J.

C., & Moreno-Medina, V. R. (2021). Perspectivas Del Consumidor Mexicano

Sobre La Calidad De La Carne De Bovino. Perspectives Of Mexican Consumer on Beef Quality. Tropical

and Subtropical Agroecosystems, 24,85. DOI:

http://dx.doi.org/10.56369/tsaes.3702.

11. Pérez-Álvarez, J. A.;

Fernández-López, J.; Sayas-Barberá, M. E.; Cartagena-García, R. (1998).

Caracterización de los parámetros de color de diferentes materias primas usadas

en la industria cárnica. Eurocarne 63, 115-122

12. Salueña, B. H., Gamasa, C.

S., Rubial, J. M. D., & Odriozola, C. A. (2019). CIELAB color paths during meat shelf life. Meat science,

157, 107889. DOI: 10.1016/j.meatsci.2019.107889.

13. Santos, M. D., Castro, R.,

Delgadillo, I., & Saraiva, J. A. (220). Improvement of the refrigerated preservation technology by

hyperbaric storage for raw fresh meat. Journal of the Science of Food and

Agriculture, 100(3), 969-977. DOI: 10.1002/jsfa.10083.

14. Sanmartín, P., Fuentes, E.,

Serrano, M., & Prieto, B. (2021). Methodological

aspects for the determination of color in soil-plant relationship studies.

15. Sun, X., Young,

J., Liu, J. H., & Newman, D. (2018). Prediction of pork loin quality using

online computer vision system and artificial intelligence model. Meat science,

140, 72–77. https://doi.org/10.1016/j.meatsci.2018.03.005.

16. Wu, D., Sun, D.

(2013). Colour measurements by computer vision for food quality control A

review. Trends in Food Science and Technology, 29(1), 5-20. https://doi.org/10.1016/j.tifs.2012.08.004.

17. Wyszecki, G.,

& Stiles, W. S. (2000). Color science. Concepts and methods, quantitative

data and formulae Jonh Wiley and Sons, Inc Second.

18. Zaukuu, J. L. Z.,

& Tsyawo, E. C. (2024). Rapid and non-destructive detection of ponceau 4R

red colored pork. Meat Science, 209, 109400. 10.1016/j.meatsci.2023.109400.

FINANCING

No financing.

CONFLICT OF INTEREST

The authors declare that there is

no conflict of interest.

AUTHORSHIP CONTRIBUTION

Formal analysis:

Olga Lucía Torres Vargas; Mateo Valencia Buitrago.

Supervision: Olga

Lucía Torres Vargas; Mateo Valencia Buitrago.

Display: Olga

Lucía Torres Vargas; Mateo Valencia Buitrago.

Drafting - original

draft: Olga Lucía Torres Vargas; Mateo Valencia

Buitrago.

Writing - proofreading

and editing: Olga

Lucía Torres Vargas; Mateo Valencia Buitrago.

![]()