doi: 10.62486/latia2024105

ORIGINAL

Classification of tomato ripeness in

the agricultural industry using a computer vision system

Clasificación de la madurez de tomates

en la industria agrícola mediante un sistema de visión artificial

Mateo Valencia Buitrago1 *, Olga Lucía Torres Vargas2 *

1Universidad

del Quindío, Ingeniería Electrónica, Facultad de Ingeniería. Colombia.

2Universidad

del Quindío, Ingeniería de Alimentos, Instituto Interdisciplinario de las

Ciencias. Colombia.

Cite as: Valencia

Buitrago M, Torres Vargas OL. Classification of tomato ripeness in the

agricultural industry using a computer vision system. LatIA. 2024; 2:105. https://doi.org/10.62486/latia2024105

Submitted: 05-02-2024

Revised: 11-05-2024 Accepted: 15-08-2024

Published: 16-08-2024

Editor: Prof.

Dr. Javier González Argote

ABSTRACT

Machine vision systems (SVA) occupy an

important place in the field of food and agriculture, these techniques are

performed in situ, are efficient, non-invasive, time-saving and more economical

than traditional techniques. Tomatoes (Solanum lycopersicum) are extensively

cultivated throughout the world, are essential in the agricultural and culinary

fields and are recognized for their beneficial contributions to health. Lack of

knowledge about fruit maturity, proper harvesting and postharvest handling are

factors responsible for large postharvest losses. Therefore, the objective of

this research was the construction of a VAS that allows establishing

relationships between color and maturity stage of the Chonto Roble F1 tomato.

The VAS built is composed of hardware and software duly synchronized through

the application of computer vision algorithms in Python 3.9 software that allow

it to perform the acquisition and segmentation of the image and present the

user with the color coordinates in the CIEL*a*b* system. Finally, color

measurements were performed on tomato samples at different stages of ripening

in the VAS and a HunterLab ColorQuest XE (EHL) spectrophotometer. The results

obtained indicated that there are no significant differences in both

measurement systems for L* values, the changes produced in b* and a* were

statistically significant for tomato samples. The results obtained indicated

the potential use of the constructed VAS for the determination of the degree of

maturity of tomatoes in real time, in a non-invasive and low-cost way.

Keywords: Image Analysis; CIEL*a*b*; Spectrophotometer; Machine Vision

System; Tomato.

RESUMEN

Los sistemas de visión artificial (SVA) ocupan un lugar

importante en el campo de la alimentación y la agricultura, estas técnicas se

realizan en sitú, son eficientes, no invasivas, ahorran tiempo y son más

económicas que las técnicas tradicionales. Los tomates (Solanum

lycopersicum), son cultivados extensivamente en

todo el mundo, son esenciales en el ámbito agrícola y culinario y son reconocidos por sus aportes

benéficos a la salud. La falta de conocimiento sobre la madurez del fruto, una

cosecha adecuada y el manejo postcosecha son factores responsables de grandes

pérdidas postcosecha. Por lo tanto, el objetivo de esta

investigación fue la construcción de un SVA que permite establecer relaciones

entre el color y el estado de madurez del tomate Chonto Roble F1. El SVA

construido está compuesto por un hardware y un software debidamente sincronizados

mediante la aplicación de algoritmos de visión computacional en el software

Python 3.9 que le permiten realizar la adquisición y segmentación de la imagen

y presentar al usuario las coordenadas de color en el sistema CIEL*a*b*.

Finalmente fueron realizadas medidas de color en muestras de tomate con

diferentes estados de maduración en el SVA y un espectrofotómetro HunterLab

ColorQuest XE (EHL). Los resultados obtenidos indicaron que no hay diferencias

significativas en ambos sistemas de medida para los valores de L*, los cambios

producidos en b* y a* fueron estadísticamente significativos para las muestras

de tomate.

Los resultados obtenidos indicaron el potencial uso del SVA construido, para la

determinación el grado de madurez de tomates en tiempo real, de una forma no

invasiva y a bajo costo.

Palabras

clave: Análisis de Imagen; CIEL*a*b*; Espectrofotómetro;

Sistema de Visión Artificial; Tomate.

INTRODUCTION

Tomatoes,

grown extensively throughout the world, are valuable not only for the

livelihood they provide to farmers and consumers but also for their health

benefits, containing vitamin C and lycopene (Ciptaningtyas et al., 2022), the

latter of which can reduce the risk of breast and prostate cancer,

osteoporosis, cardiovascular disease and reduce high blood pressure (Przybylska

&Tokarczyk, 2022). However, a lack of knowledge about maturity and

postharvest handling contributes to growers' huge losses today. The assessment

of tomato maturity and quality depends largely on the external characteristics

of the fruit; its assessment can be done using non-invasive methods (Ninja

& Manuj-Kumar, 2022). Assessing maturity and harvesting a product at the

right stage is an art that differs from crop to crop; maturity is an

irreversible process that directly affects the internal and external quality of

the fruit (Prasad et al., 2018). During tomato cultivation, it is common to

consider six stages for tomato color ripening (Maturity and ripening stages):

green, brittle, turning, pink, light red, and red; in addition to the

development of flavor, texture, and aroma, these ripening stages in tomatoes

occur from greenhouse or growing plot, transportation, purchase, shelf, refrigeration

to consumption (Hongli et al., 2023).

Electronic

machine vision systems (EVS) represent an emerging technique in food and

agriculture; they play an important role in solving practical problems of

automatic sorting and recognition. These techniques have surpassed manual labor

and are non-invasive, time-saving, economical, rigorous, and accurate. Research

using VAS for color assessment in food has focused on the conversion of images

obtained using the RGB color measurement system to the CIEL*a*b* system

(Larraín et al., 2008); several approaches have been explored in this field,

including the examination of color indices about tomato ripeness and the use of

image processing. Khan et al. 2011 conducted studies for tomato maturity

recognition with convolutional transformers, Konagaya et al. 2020 monitored the

quality of ripe tomato (red stage) during storage using image processing images

red) during storage using ultraviolet light-induced visible fluorescence

imaging, Changxia et al. (2021) formulated a tomato ripeness recognition

algorithm based on a multilevel deep residual network, Nassiri et al. (2022)

used fuzzy logic classification on ripe tomatoes based on physical property

fusion. Sharma et al. (2020) implemented a ripening index for color-based

evaluation of the ripening behavior of tomato fruits. Color assessment should

be performed consistently and objectively to obtain reliable and reproducible

results that reflect human perception and can be performed in a non-invasive

manner (Wu et al., 2013). Therefore, this research's objective was to construct

a VAS that establishes relationships between color images in CIEL*a*b*

coordinates and the maturity stage of the Chonto Roble F1 tomato.

METHOD

For

the development of the research presented below, a machine vision system (SVA)

was built and implemented to classify tomatoes by their maturity stage based on

the CIEL*a*b* color spaces (1986).

Raw material

Tomatoes

(Solanum lycopersicum) of Roble F1 variety, harvested from farms in the Quindío

region, representing an important part of the department's economy, were used

as raw material. The color of the pericarp visually classified the tomatoes,

applying the ripening stage criteria established by the Colombian Technical

Standards ICONTEC for tomatoes (NTC 1103-1). Once selected, these were analyzed

in the SVA and EHL.

Machine Vision

System (SVA)

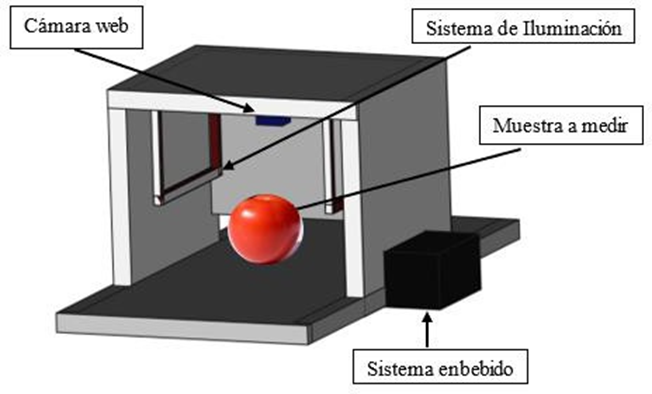

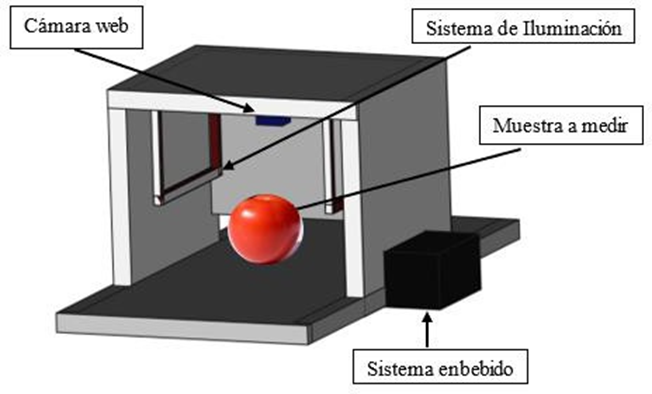

To

carry out the process of taking color images of the tomato samples, a VAS was

built using a low-cost Logitech PRO C920 Full HD digital camera, graphic

processing units (GPU), data storage devices, and an illumination device

(series of LEDs)—the programming of the hardware.

The

hardware measurement system was programmed using Python 3.9. Both systems,

properly synchronized, are responsible for presenting to the user the CIEL*a*b*

coordinates of tomato samples with different days of ripening.

Figure 1. Machine Vision System

(SVA) for the measurement and analysis of color in tomato samples

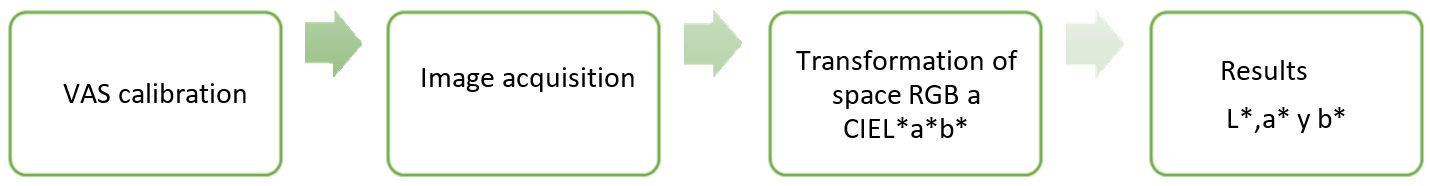

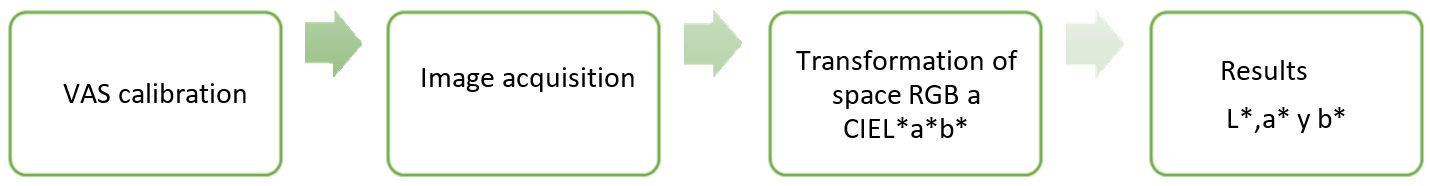

For the implementation of the VAS, we

proposed the design of software that allows the calibration of the camera and

the detection of the color of tomatoes with different degrees of ripeness,

following the steps shown in figure 2.

Figure 2. Stages established in the design and construction of the

software for the Machine Vision System (SVA)

The

backbone of the VAS consists of an embedded system, implemented in a Raspberry

Pi 4, running the Raspberry Pi OS operating system, which is in charge of capturing

the image, segmenting it, resizing it, storing it, and delivering a response in

terms of CIEL*a*b* coordinates to the user (Valencia, 2023).

Prior

to image capture, a calibration stage was performed. The color was determined

using a Logitech PRO C920 camera, which offers advantages such as the capture

of a large amount of spatial information, the ability to measure surfaces of

various sizes, the availability of a wide range of models at more affordable

prices, and not require direct contact with the surface to be measured.

However, using theoretical models, the information obtained in color space Red,

Green, and Blue (RGB) must be transformed to CIEL*a*b* color space (Castellanos

et al., 2022). The parameters and equations used at this stage are presented in

table 1.

|

Table 1. Color characterization in tomato: equations and specialized

equipment.

|

|

Parameters

|

Equations

|

Color measurement

equipment

|

|

Brightness: L*

|

L* = 116 (Y1/3/Yn)− 16 Ec.(1)

|

|

|

Coordinate coordinate: a*

|

a* = 500 [(X1/3/Xn)−

(Y1/3/Ym)] Ec. (2)

|

|

Coordinate coordinate: b*

|

b* = 200 [(Y1/3/Yn)

− (Z1/3/Zn)] Ec. (3)

|

HunterLab

Spectrophotometer

ColorQuest XE (EHL).

|

In

order to establish a comparison parameter, color measurements were made in the

VAS and EHL on tomatoes with different degrees of ripening (table 3). The

coordinates L*, a*, b* in the EHL system were taken using a D65 lamp, 1 cm

diameter aperture, and a 2° standard observer at five points on the pericarp of

each tomato sample and the values reported were calculated as the average of

these measurements. The determination and expression of color were carried out

based on CIEL*a*b* coordinates (table 1) and reflectance values (CIE, 1986),

obtaining the parameters of Luminosity (L), red-green (a*), yellow-blue (b*)

directly from the equipment.

Statistical

analysis

To

establish if there are differences between the color measurements made by the

SVA and the EHL, an analysis of variance (ANOVA- Multifactorial) by least

significant difference (LSD) with p-value ≤ 0.05 was performed, with three

interaction factors, taking as response variables the coordinates L*, a*, b*,

and as a factor: the degree of maturation. This analysis was performed using

the statistical package Stratigraphic ® Plus, Centurion.15.2.12 XV (Numagistics

Ltda).

RESULTS

AND DISCUSSION

Once

the construction of the electronic system and the programming of the VAS

hardware measurement system in its structural form were completed, a

compartment was built for image acquisition, which functions as the main

structure of the equipment, supports the tomato sample to be analyzed and the

other components, as can be seen in figure 1.

The

image is captured by the Logitech PRO C920 camera and subjected to an analysis

process to reduce noise and improve its quality; contrast and color correction

adjustments were also made to optimize its usefulness in subsequent analyses.

After the previous stage, the image was segmented to identify the region of

interest (ROI) within the obtained tomato image. This segmentation involved

advanced image processing techniques, such as thresholding and threshold

detection.

This

segmentation involved using advanced image processing techniques such as

thresholding and feature detection to distinguish the ROI from the background

and other irrelevant elements. The identified region of interest becomes the

main focus of further analysis and applications, allowing feature detection,

pattern recognition, and decision-making based on accurate and relevant visual

information.

The

acquired image is processed by Python 3.9 software and converted from RGB space

to CIEL*a*b* space using equations (1), (2), and (3) presented in table 1. The

system computes the mean of the Luminance (L*), red-green (a*), and yellow-blue

(b*) coordinates. Finally, the user will be able to visualize both components

facing the original tomato image in the interface, and this information will be

stored on the computer.

Table

2 shows the L*, a*, and b* coordinates obtained in the epicarps of the six

tomato samples analyzed with different degrees of ripening in the SVA and EHL.

The tomato ripening process is characterized by a high synthesis of carotenoids

that generates changes in the L*, a*, and b* coordinates (Artés-Calero &

Artés-Hernández, 2004). The* coordinate presented significant changes; samples

1 and 2 presented negative values (green color) that progressively became

positive (red color). López-Camelo et al. (2003) point out that during tomato

ripening, phytoene (colorless) is initially synthesized, to later give rise to

ζ-carotene (pale yellow), lycopene (red), β-carotene (orange) and xanthophylls

and hydroxylated carotenoids (yellow); as we can observe in samples 3 and 4.

The

synthesis of yellowish pigments precedes reddish pigments, but the massive

accumulation of the latter masks the former. When the red pigments began to be

synthesized, a decrease in the values of the L* coordinate occurred, indicating

a darkening or decrease in brightness, as seen in samples 5 and 6 (table 3).

The changes in the b* coordinate were not significant.

Table

3 shows the values for L*, a*, and b* coordinates obtained in the VAS and EHL

for tomatoes at different maturity levels. The values obtained do not show

significant differences, indicating the potential use of the VAS in the

selection of tomatoes by maturity level.

Table

3. Results for L*, a* and b* coordinates

obtained in the VAS and EHL for tomatoes at different maturity levels

|

|

Sistema de Visión Artificial

|

HunterLab Spectrophotometer

|

|

Samples

|

L*

|

a*

|

b*

|

L*

|

a*

|

b*

|

|

1

|

85,42±0,35

|

-10,06±0,16

|

70,73±0,68

|

82,19±0,44

|

-9,06±0,09

|

68,21±0,08

|

|

2

|

81,58±0,19

|

-5,68±0,13

|

71,25±1,05

|

80,71±0,70

|

-6,25±0,72

|

67,17±1,20

|

|

3

|

78,99±0,59

|

12,56±0,98

|

72,25±0,74

|

76,14±0,04

|

8,56±0,95

|

69,54±0,91

|

|

4

|

70,23±0,52

|

21,68±0,53

|

73,80±0,60

|

69,4±0,06

|

20,15±0,90

|

68,70±0,08

|

|

5

|

66,05±0,27

|

31,47±0,31

|

73,28±0,94

|

65,97±0,19

|

33,62±1,06

|

69,12±0,02

|

|

6

|

62,28±0,03

|

43,93±0,07

|

70,41±0,70

|

60,57±1,05

|

44,08±1,53

|

68,32±0,21

|

The

results obtained made it possible to evaluate the use of the VAS constructed to

determine color as a parameter for classifying the ripening stage of tomatoes

in a non-invasive, economical, and real-time manner. Farmers can use this technological

tool to inspect, classify, and estimate the maturity of fruit and vegetable

products and determine the optimum time to harvest them, increasing their

productivity and strengthening the Colombian fruit and vegetable chain.

CONCLUSIONS

The

methodology used by the developed VAS allows for analyzing the global color of

the sample and its heterogeneity, captures, processes, analyzes the images, and

evaluates the color non-invasively, using the CIEL*a*b* coordinates. This

system offers the possibility of analyzing the entire surface of the product,

its characteristics, and defects, allowing you to estimate the state of

maturity quickly and at a low cost, factors that differentiate it from a

commercial spectrophotometer. The images obtained allow the farmer to classify

unripe, ripe, and overripe fruit for subsequent marketing or agro-industrial

processing.

BIBLIOGRAPHIC REFERENCES

1.

Artés-Calero, F., Artés-Hernández, F. 2004. Tratamientos postrecolección del

tomate fresco. Tendencias e innovaciones, Capítulo 10, pp. 109-120. In:

Tomates. Producción y comercio. Ediciones de Horticultura S.L. Reus, España.

ISBN 84- 87729-48-7.

2.

Castellanos Tolosa, N y Sánchez Jiménez, M. (2022). Desarrollo de carne de

hamburguesa a base de harina de grillo. Universidad de los Andes. Disponible

en: http://hdl.handle.net/1992/55654.

3.

Changxia Li, Xuemei Hou, Nana Qi, Huwei Liu, Yihua Li, Dengjing Huang, Chunlei

Wang, Weibiao Liao. (2021). Insight

into ripening-associated transcription factors in tomato: A review, Scientia

Horticulturae,Volume, 288,110363. https://doi.org/10.1016/j.scienta.2021.110363

4.

Ciptaningtyas, D., N. Benyakart, H. Umehara, M. Johkan, N. Nakamura , M. Nagata

, T. Orikasa , M. Thammawong , T. Shiina. (2022)

Modelado del patrón de maduración metacrónica del tomate verde maduro afectado

por el cultivo y la temperatura de almacenamiento Ciencia. Rep., 12, pág. 8241 , https://doi.org/10.1038/s41598-

022-12219-z.CIE (1986) Colorimetry. 2nd Ed. CIE 15.2: Viena

5.

Larraín, R., Schaefer, D., Reed, J. (2008). Use of digital images to estimate

CIE color coordinates of beef. Food Research International, 41(4), 380-385.

6.

Hongli Li, Gangshuai Liu, Daqi Fu. (2023).Transcriptional regulation of tomato

fruit quality, Postharvest Biology and Technology,Volume 202,112393, https://doi.org/10.1016/j.postharvbio.2023.112393.

7.

López-Camelo, A.L., Gómez, P., Artés, F. (2003). Use of a* and b* colour parameters to assess the effect of

some growth regulators on carotenoid biosynthesis during postharvest tomato

ripening. Acta Horticulturae 599:305-308.

8.

Nassiri, S. M., Tahavoor, A., & Jafari, A. (2022). Fuzzy logic

classification of mature tomatoes based on physical properties fusion.

Information Processing in Agriculture, 9(4), 547-555. DOI:

2017.63807ijbse10.22059

9.

Ninja Begum, Manuj Kumar Hazarika. (2022).Maturity detection of tomatoes using

transfer learning, Measurement: Food, Volume 7,100038. https://doi.org/10.1016/j.meafoo.2022.100038.

10.

Instituto Colombiano de Norma Tecnica y Certificaión. Industria Alimentaria:

Tomate de Mesa. Bogotá, D.C.: ICONTEC, 1995. Bogotá, D.C.: ICONTEC, 1976.

(Norma Técnica Colombiana; NTC- 1103-1).

11.

Khan, A., Hassan, T., Shafay, M., Fahmy, I., Werghi, N., Mudigansalage, S.,

& Hussain, I. (2023). Tomato maturity recognition with convolutional

transformers: Scientific Reports. Sci. Rep., 13(1). https://doi.org/10.1038/s41598-023-50129-w

12.

Konagaya, Keiji., Dimas Firmanda Al Riza, Sen Nie, Minori Yoneda, Takuya

Hirata, Noriko Takahashi, Makoto Kuramoto, Yuichi Ogawa, Tetsuhito Suzuki,

Naoshi Kondo. (2020), Monitoring mature tomato (red stage) quality during

storage using ultraviolet-induced visible fluorescence image, Postharvest

Biology and Technology, Volume 160,111031. https://doi.org/10.1016/j.postharvbio.2019.111031.

13.

Prasad, K., Sanu Jacob, Mohammed Wasim Siddiqui, Chapter 2 - Fruit Maturity,

Harvesting, and Quality Standards, Editor(s): Mohammed Wasim Siddiqui,

Preharvest Modulation of Postharvest Fruit and Vegetable Quality, Academic

Press, 2018, Pages 41-69, https://doi.org/10.1016/B978-0-12-809807-3.00002-0.

14.

Przybylska, S., & Tokarczyk, G. (2022). Lycopene in the Prevention of

Cardiovascular Diseases. International journal of molecular sciences, 23(4),

1957. https://doi.org/10.3390/ijms23041957

15.

Sharma, L. K. Ramesh , V. Paul , R. Pandey.( 2020

). Índice de maduración: un mejor parámetro para la evaluación basada en el

color del comportamiento de maduración de los frutos de tomate. Fisiol vegetal.

Rep. , 25, págs . 171-177 , https://doi.org/10.1007/s40502-020-00499-4

16.

Valencia, M. (2023). Desarrollo de un sistema de visión artificial para el

monitoreo de los cambios de color en lomos de bovino. [Tesis,Universidad del

Quindio]. bdigital.uniquindio.edu.co.

17.

Wu, D., Sun, D. (2013). Colour

measurements by computer vision for food quality control A review. Trends in

Food Science and Technology, 29(1), 5-20. https://doi.org/10.1016/j.tifs.2012.08.004.

FINANCING

The

authors did not receive financing for the development of this research.

CONFLICT OF INTEREST

The

authors declare that there is no conflict of interest.

AUTHORSHIP CONTRIBUTION

Conceptualization:

Mateo Valencia Buitrago, Olga Lucía Torres Vargas.

Investigation:

Mateo Valencia Buitrago, Olga Lucía Torres Vargas.

Methodology:

Mateo Valencia Buitrago, Olga Lucía Torres Vargas.

Drafting

- original draft: Mateo

Valencia Buitrago, Olga Lucía Torres Vargas.

Writing

- proofreading and editing: Mateo

Valencia Buitrago, Olga Lucía Torres Vargas.

![]()